Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 7 of 7

Thread: BXA QCTP from CDCO

-

3rd October 2012, 10:09 PM #1

BXA QCTP from CDCO

BXA QCTP from CDCO

Hi all,

As luck would have it USPS did a good job with one of my boxes from CDCO.....the tracking on the other says its still in Chicago

I had no idea what would be in the box when i got it this morning but after busting through the tape i found a lonely tapping guide and my toolpost .

.

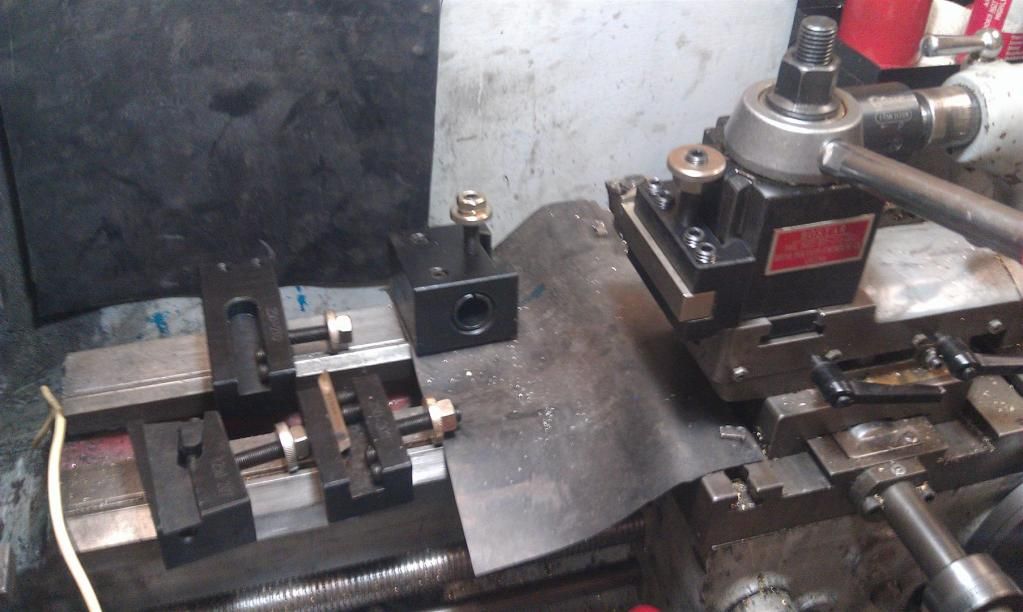

So i actually did something this arvo and machined the t nut to fit the compound and bolted it on. Wow...thats the most i've done in 2 weeks!

Overall i'm happy with the quality, but there is certainly a couple of things to fix. Firstly i stripped it down and started cleaning all the browny red "grease" (for want of a better word) out. Every time i touched the post more of it would ooze out of it.

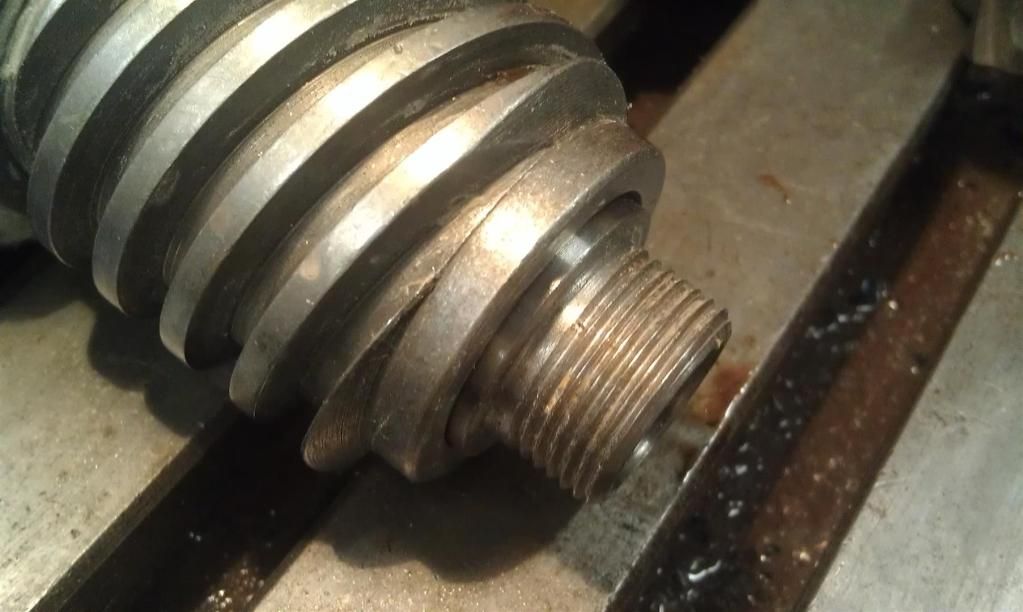

The other main problem is in the length of the central bush. It is .065" longer than the worm (the last pic makes the problem pretty clear) so there is a huge amount of backlash when tightening and loosening the holders. I will shim it for now but i think a new bush is on the cards as i think it could be a better fit in the worm too.(haven't measured it yet)

For $129 plus postage they are a LOT cheaper than the genuine Aloris ones, a BXA post with no holders will set you back $335 plus post!

I still have to put a spring loaded pin in the t nut for easy alignment, but it was good to make some chips!

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

3rd October 2012 10:09 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

3rd October 2012, 10:26 PM #2Dave J Guest

Thats going to make life easy. A lot of guys make another handle instead on the nut on top, that way you can index the tool post easier.

Dave

-

3rd October 2012, 10:43 PM #3

Philomath in training

Philomath in training

- Join Date

- Oct 2011

- Location

- Adelaide

- Age

- 59

- Posts

- 3,149

They are wonderful things!

I bought my first QCTP from Shars and found that although the sockets were imperial, the threads were actually metric. It may be worth heading to the local fastener place and buying some longer grub screws for the depth stop and some quality grub screws for holding the tools as the original ones were not the best quality. (Do a light touch on a grinding wheel to take the knurl off the bottom of the G.S. for smooth clamping)

A new Aloris is expensive, but I bought mine second hand and it was probably not much more than what you paid. I have heard of one complaint that a second hand QCTP was too worn to use, but that would require a lot of work on a properly hardened post I would have thought.

Michael

-

4th October 2012, 12:57 AM #4

It will make life a lot easier...once i make a few dozen holders

add it the to-do list......

add it the to-do list......

Michael, you are right about the grub screws, they are M10, but the socket is crap, 5mm is sloppy but a 7/32 is too big. I'll probably only end up using the HSS parting holder long term, and make my own for the rest. The quality of the holders is particularly poor....but extra's are 1/5 of the price of H&F so i can't really complain.1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

4th October 2012, 01:31 AM #5

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2007

- Location

- sydney

- Age

- 64

- Posts

- 3,566

Is the position of the tool in the holder the actual working position or hadnt you adjusted it.

The position of the knurled nut and hex nut are ar-e about.

-

4th October 2012, 05:40 AM #6

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2006

- Location

- Adelaide

- Posts

- 2,680

how long has CDCO had wedge type QCTP's?

-

4th October 2012, 11:14 PM #7

The nuts are ar5e about because the stingy buggers have used grub screws that are too short to give full height adjustment.

Continuing on from my math thread https://www.woodworkforums.com/f65/ca...y-math-160027/ (since it was really only about the math) the locking handle varies by about 1/8 of a turn with different holders......

I spent some more time in the shed today (maybe a bit too much) and made a new bush. Not only was the original .065" long it was .040" smaller than the bore of the worm. Luckily it had a metric thread on the end, so i could make it without pitch problems or having to waiting until i made my 127/120t gears. Its been several years since i did any threading but i managed to get it right first go I must say a big thumbs up to tap magic as a fluid, i have never used it before for threading on the lathe but it worked very very well.

I must say a big thumbs up to tap magic as a fluid, i have never used it before for threading on the lathe but it worked very very well.

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

Similar Threads

-

CDCO chuck

By morrisman in forum METALWORK FORUMReplies: 24Last Post: 2nd March 2012, 08:53 PM -

CDCO .... is he still around

By morrisman in forum METALWORK FORUMReplies: 3Last Post: 24th September 2011, 02:51 PM -

CDCO.....again

By Sterob in forum METALWORK FORUMReplies: 14Last Post: 19th October 2010, 07:51 PM -

Cdco

By Toggy in forum METALWORK FORUMReplies: 18Last Post: 11th June 2010, 05:43 PM