Results 151 to 165 of 948

Thread: Whisperings

-

15th Dec 2011, 06:42 PM #151

Most Valued Member

Most Valued Member

- Join Date

- Sep 2011

- Location

- Ballarat

- Age

- 65

- Posts

- 3,103

-

15th Dec 2011, 10:49 PM #152

Hi Phil,

I remember meeting up with an ex-manager who turned up serving tables in a restaurant... now that was weird... he seemed happier than when I remembered him from before, I think he finally found a job matched to his skill level....

Regards

Ray

PS I'll post those wheel rim pictures and write up in a while, just back from a long trip...

-

15th Dec 2011, 11:25 PM #153

Hi Stuart,

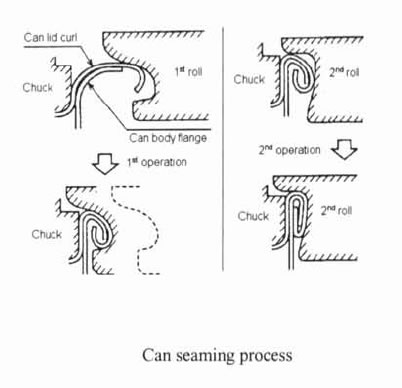

This might help...

The pictures don't show the sealing compound which is on the inside of the lid.

Regards

Ray

-

15th Dec 2011, 11:42 PM #154

Most Valued Member

Most Valued Member

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 9,088

Hi Ray,

I'd been thinking about Phil had said most of the day. I've been think "folding" to much and not enough rolling. Its easy once someone else has thought of it lol

Thanks guys

Stuart

-

16th Dec 2011, 05:08 PM #155

A clever bit of engineering

A clever bit of engineering

Wagon wheel design and construction is not something I admit to having given a lot of thought to, but when you get to see first hand what goes into making a wheel, and some of the subtleties of the design, that you get to appreciate what a truly brilliant bit of engineering they are..

First, the only thing holding the wheel together is the steel tyre, which is shrunk on either with heat or with a hydraulic shrinking device.

Pause for a minute and imagine the stresses that these wheels have to endure bouncing at speed across rough rocky terrain. Some of the carriages on display had incredibly light spindly looking wheels..

The secret is in the way everything locks together and the spokes are shaped to be like springs in one direction and stiff in the other, hence the elliptical profile of the spokes.

Back to steel tyres.. I guess it's about 20mm thick (Phil might help out here) and the tyres are rolled on this machine..

Here are some tyres ready to be forge welded to size..

Once the tyres are sized for the wheel, the traditional method is to heat and slip over the wheel, then cool the tyres before the wood catches fire...

There is a special area where they could flood the wheel with water..

The other method is a hydraulic shrinking machine.

They actually have one of these machines, we didn't see it operating, but the guide explained that they squeeze it a bit , then rotate the wheel a little before the next squeeze, thus eliminating bumps, the steel compresses one way and expands across width of the tyre a little, ending up with tight fit, one thing that is critical is the wheel has to be a bit springy in the radial direction, to get a good tight fit to the tyre, if it's too stiff radially it doesn't work properly.

Finally a wheel

I'll be watching those old westerns where the stagecoach is bouncing across the desert more closely in future...

Harty, if you have any more of those brilliant pictures please post them.

Regards

Ray

PS Thanks again to Phil

Last edited by RayG; 16th Dec 2011 at 08:45 PM. Reason: Spelling...

-

16th Dec 2011, 08:35 PM #156

Most Valued Member

Most Valued Member

- Join Date

- Sep 2011

- Location

- Ballarat

- Age

- 65

- Posts

- 3,103

Hi Ray,

they vary in thickness. The ones for the coaches are about 20mm thick. Other wheels are made with 10mm hoops and then there is the dray with the wool bales on it, those hoops are about 25mm thick.

Here is a pic of my next major project.

It is a 'Weirs' boiler feed pump and stands nearly 9 feet tall (about 2.7 metres)

It is going to get a cosmetic rebuild first and as time permits I have to get it running again

Phil

-

16th Dec 2011, 08:56 PM #157

Phil, what kind of pressure does that Weir pump have to make to overcome the boiler pressure? And does it pulse in operation? (I can't quite make out the connecting rod detail)

Best,

GregIt's all part of the service here at The House of Pain™

-

16th Dec 2011, 10:17 PM #158

Most Valued Member

Most Valued Member

- Join Date

- Sep 2011

- Location

- Ballarat

- Age

- 65

- Posts

- 3,103

Hi Greg

these pumps are run using steam from the boiler which acts on a large piston. The piston rod has a smaller piston connected to the other end which pushes the water. This way it doesn't matter what the boiler pressure is, the pump will overcome it.

ie large surface area pushing a small surface area.

This link is one I prepared earlier

Phil

Welch Perrins (5).MOV - YouTube

ps I have just uploaded so am not sure if it is available yet

-

16th Dec 2011, 10:24 PM #159

I'll give myself a head slap for that one now as I do recall you described its action in detail on Sunday. And you're right about the elegance and simplicity of large piston/small piston auto pressure regulation.

GregIt's all part of the service here at The House of Pain™

-

16th Dec 2011, 10:30 PM #160

Most Valued Member

Most Valued Member

- Join Date

- Sep 2011

- Location

- Ballarat

- Age

- 65

- Posts

- 3,103

No need for the head slap Greg. I may have given you blokes a bit of information overload that day

Phil

-

16th Dec 2011, 10:33 PM #161

Yeah maybe...I remember the boilers, and the quartz, but not how the boiler turns the quartz into gold. Was that in the ferrier's shop? I wasn't paying attention there because he scared me.

It's all part of the service here at The House of Pain™

-

16th Dec 2011, 10:39 PM #162

Most Valued Member

Most Valued Member

- Join Date

- Sep 2011

- Location

- Ballarat

- Age

- 65

- Posts

- 3,103

-

16th Dec 2011, 11:11 PM #163

Most Valued Member

Most Valued Member

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 9,088

Hi Phil,

Is there any control over speed or is it just on or off? Looks like it would run forever at that speed.

The pump is easy, its injectors I have trouble getting my head around. Got any of those laying around Phil?

Stuart

-

17th Dec 2011, 07:08 AM #164

Most Valued Member

Most Valued Member

- Join Date

- Sep 2011

- Location

- Ballarat

- Age

- 65

- Posts

- 3,103

Hi Stuart,

There is plenty of control over speed. These pumps can run so slow that you can hardly see them moving at all and by using the throttle valve can be made to run so fast, they will destroy themselves. You would find these types of pumps on ships as they didn't take up much floor space and could be kept running slowly on standby or adjusted to keep up with the amount of water being evaporated from the boilers.

You constantly amaze me. I don't know many people who have even heard about injectors. I have donated a one and a half inch Brown Auto Positive injector that is to be installed on our boilers. They are the most amazing things. They use the source steam pressure and mix it with water to overcome the same source pressure. You would naturally think that if you put water into steam it's pressure would drop, and it does, but, by the use of diverging and converging cones the velocity is increased and brute force then overcomes the source steam pressure. Think of it like this. your garden hose has a converging cone, if you put a liquid (water) through this, it's velocity increases. If you put a gas (steam) through a diverging cone, it's velocity increases. Think of an expansion valve in refrigeration. If you combine the two, you get some serious pressure out the other end. The beauty of this is, no moving parts. The injector I have donated is capable of shifting between 3000 and 9000 litres of water an hour. I havent had much to do with locomotive type injectors but they are the same principle only with more flow adjustment unlike the Auto Positive which has limited flow adjustment.

Badly explained I know, so don't hesitate to ask for any clarification.

Remember this explanation is very basic. It would probably take me a week to explain it fully as it is also about densities and mixing rates and cone dimensions and timing etc etc

Phil

-

17th Dec 2011, 07:23 AM #165

That's the same basic principle of the scavenge pumps in large aircraft fuel tanks. We use motor pump driven fuel as the motive force in the ejector pumps. I'm rather fond of their explosion proof nature.

GregIt's all part of the service here at The House of Pain™

Thanks:

Thanks:  Likes:

Likes:  Needs Pictures:

Needs Pictures:  Picture(s) thanks:

Picture(s) thanks:

Reply With Quote

Reply With Quote