Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 32

-

8th Nov 2012, 08:11 PM #1

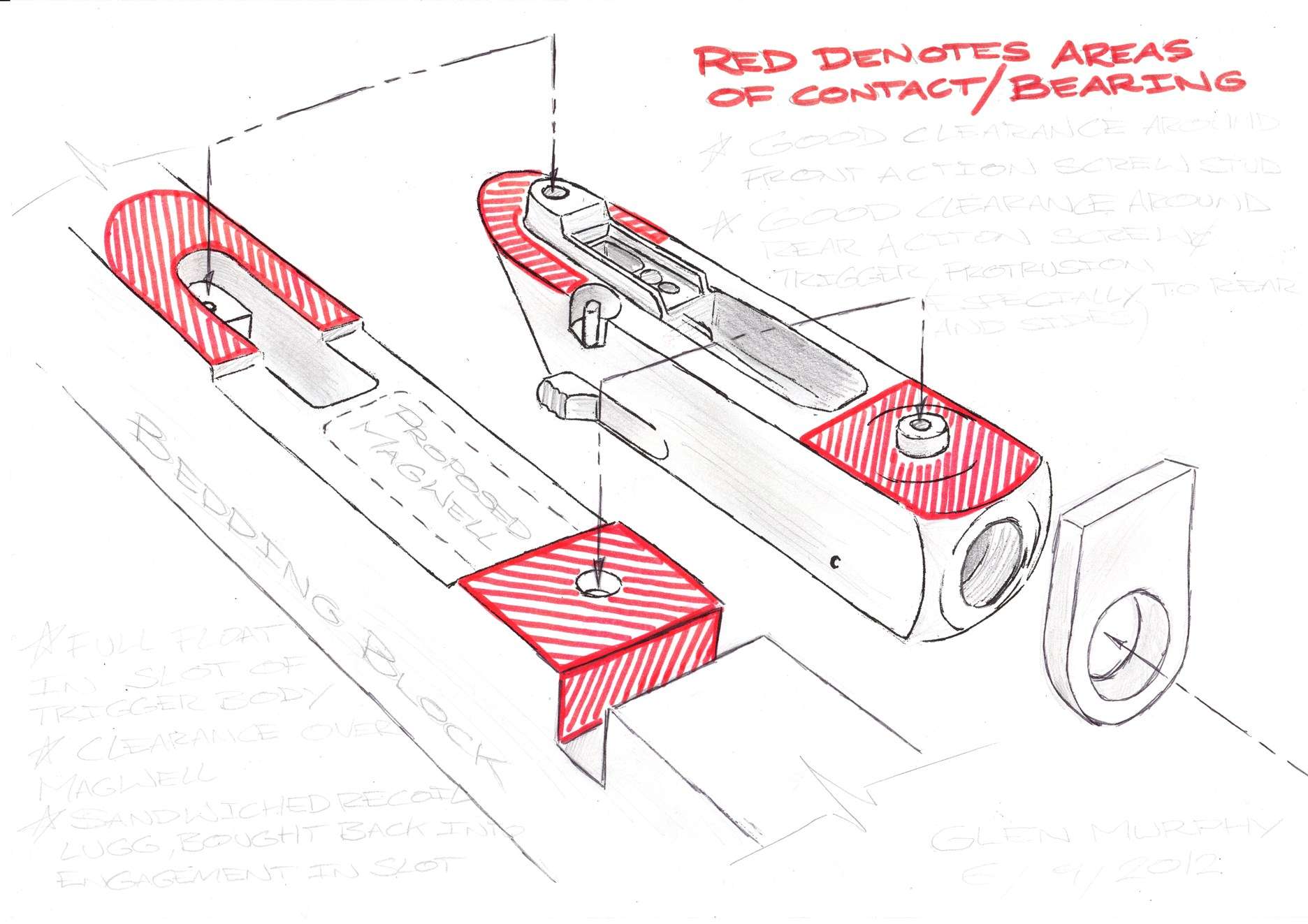

Machining a Bedding Block for the Tikka M590 (Pic Heavy)

Machining a Bedding Block for the Tikka M590 (Pic Heavy)

Hi everyone, here are some progress pictures of my current project.

It started when I saw a thread on the shooting.com.au forums: Sako 85 AICS - Shooting.com.au

I happened to have a spare barrelled action (well used) in the safe, that I had wanted to get it into a stock so it atleast had some utility, and GregT's work was just the inspiration I needed.

Once I have evaluated the barrel in it and settled on a calibre I will then look @ mag options and will complete the rest of the machining on the bedding block at that point.

And Yes, in-case anyone is wondering the tailstock was initially installed upside down ....good times, had to re-check my set-up again.

-

8th Nov 2012, 08:25 PM #2

The 17mm (nominal) Sako dovetail, in what will become the scope rail for the project.

Got most of the scope mount done now; The rib in the pictures will be cross drilled to accept the big ass rings (AD Recon) that came with the 2nd hand scope I purchased for this project. Once I've worked a few positional/ergonomics things out I can proceed further - however I'm awaiting a butpad from sporting services in the UK and until I've got this installed I'm hesitant to finalise anything incase it doesnt suit later i.e eye relief relative to natural cheekweld etc.

In the mean time I'll work toward a method of locking the dovetail, possibly like an optilock?

Would like to be able to remove scope, rings and mount as one piece (for the odd occaision it might end up on my other M590 fullbore rifle) this would effectively rule out using the tapped holes in the top of the reciever, any idea's?

This is how the scope mount is shaping up @ present

Tonight I've turned up the locking handles, cross drilled the base and milled the recesses that the SS claws fit into,

so thus it is useable in this condition. At some point I'll rework a few aesthetic things, de-burr and integrate a spirit level bubble into it somewhere on the mount, but for now i'll be happy enough to start looking at the barrell work aspect of this project

Machined up a recoil lug for this project this evening, out of some 4140.

Lapped the critical surfaces on a diamond plate, all thats left to do now is make an ammendment shoulder of the barrel so the headspace isnt out by like 315 thou' .

.

Will also mildly chamfer the face that mates with the barrel.

So getting close to the point where I can put some shots through it and assess the condition of the used barrel.

I'm thinking of going with the AI single stack magnum (.300win, 30-06 etc) length mags as there is a 10 shot available in these.

-

8th Nov 2012, 08:29 PM #3

Senior Member

Senior Member

- Join Date

- Jun 2011

- Location

- Adelaide

- Age

- 27

- Posts

- 248

Wow thats amazing, i love it

Keen to see some more updates man, keep it up!!

Cooper

-

8th Nov 2012, 08:54 PM #4

I appologise for the text appearing abit incoherent, It has been posted else where as a running commentary and thus its out of context when posted all at once.

Below are some pics for those unfamiliar with the M590 action:

From what I can gather they were a forebear to the current production Tikka T3, and visually from the topside the two look very similar, However I've the feeling that the 590 has a smaller loading/ejection port. As for the underside I can't comment as I've not seen the bedding arrangment of a T3, but know they run an insertable recoil lug.

-

8th Nov 2012, 10:17 PM #5

.

.

- Join Date

- Nov 2008

- Location

- Perth WA

- Age

- 71

- Posts

- 6,459

-

8th Nov 2012, 10:28 PM #6

Most Valued Member

Most Valued Member

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 9,088

-

8th Nov 2012, 10:36 PM #7

Thats an early touch probe/ sensor, rather than have the piezo buzzer integral in the probe like they do these days - it used the DRO unit to sound out.

And the good news is: I've not managed to fire the machine up with the probe still connected, yet

before I shoot some group's, I'll make an ammendment to the bipod spigot to allow me to lock the swivel/canting, and a few other things.

once I see how tightly it prints I'll then make some decisions regarding the replacement of the barrel and possibly calibre conversion.

-

8th Nov 2012, 10:39 PM #8

Make that a big

from me too.

from me too.

Love your mill too, i have just looked through your posting history but couldn't find any info on it....any chance of some more pics? I can see that its a euro but cannot work out the make?1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

8th Nov 2012, 11:04 PM #9

.

.

- Join Date

- Nov 2008

- Location

- Perth WA

- Age

- 71

- Posts

- 6,459

Ewan,

Glen's a farm boy. He might have headed off to bed. Have a look and read and maybe a laugh here in case he has called it a night.

http://www.woodworkforums.com/f65/ha...3/#post1385158

BT

-

8th Nov 2012, 11:09 PM #10

Riken RMT-2, Japanese clone of the Mk2 Deckel FP1 (1966 Manufacture) - got a good amount of the original matching acc/

(theres not alot of info around to be had on these, which is a bit sad - but mechanically the deckel manual I've got seem 95% interchangeable)

I'm surprising you couldnt find mention of it in my posting history: I defiled a thread of bob's about hardinge collets, and quasi turned it into a discussion about the riken and other unobtanium deckel acc/ that gregQ and I wanted.

http://www.woodworkforums.com/f65/ha...ochure-140753/

Will post further picks of it over the next few days

-

8th Nov 2012, 11:13 PM #11

Senior Member

Senior Member

- Join Date

- Apr 2010

- Location

- Rural Victoria

- Posts

- 358

Good stuff... I am also a shooter and would like to see a separate category on gunsmithing on this forum... because it is more interesting than golf.

I picked up a Dolomite (forerunner of Zeiss?) scope with the German post reticle... trouble is it only has an elevation turret, and I assume that windage was controlled by the scope mounts... I drew up a mount in Inventor, making it is requires another 'roundtoit'... with a custom mount for a K98 perhaps?

-

9th Nov 2012, 08:12 AM #12

I have heard of dolomite, will check my books for you.

Quite a few of the early Hensoldt's had no lateral adjustment integral to the tube & zero was achieved through the fit of the mount to the action.

I think then for windage adjustment the shooter held off a judged amount into the wind?

I've seen some American side mount designs of the same era, where they had a simple amount of correction in addition to this

what power is the Dolomite, I'd be interested to see what you've come up with.

I'm about to learn all about external adjustment etc, the next project on the drawing board is a Model 70 CRF w/ 8x Unertl & micrometer mounts.

-

9th Nov 2012, 10:26 AM #13

.

.

- Join Date

- Nov 2008

- Location

- Perth WA

- Age

- 71

- Posts

- 6,459

-

9th Nov 2012, 12:50 PM #14

Unfortunately not, but the more I research the current manufacture FN Herstal Win model 70's - the more I see that after along time in the wilderness, they are basically back to that controlled round feeding P'64 format and in many facet's are improved. The build quality was there all along.

So I'll likely pick one of these up in a long action and build on that.

It'll still look very authentic to what I want to reproduce, but beneath the clothing I'm looking to refine it into something capable of shooting a group into a ragged hole (when I do my bit). Might look to install a hidden AL bedding block etc. I've just found the correct win "target/marksman" stock up for the project.

-

9th Nov 2012, 02:43 PM #15

Most Valued Member

Most Valued Member

- Join Date

- Nov 2007

- Location

- melbourne australia

- Posts

- 3,228

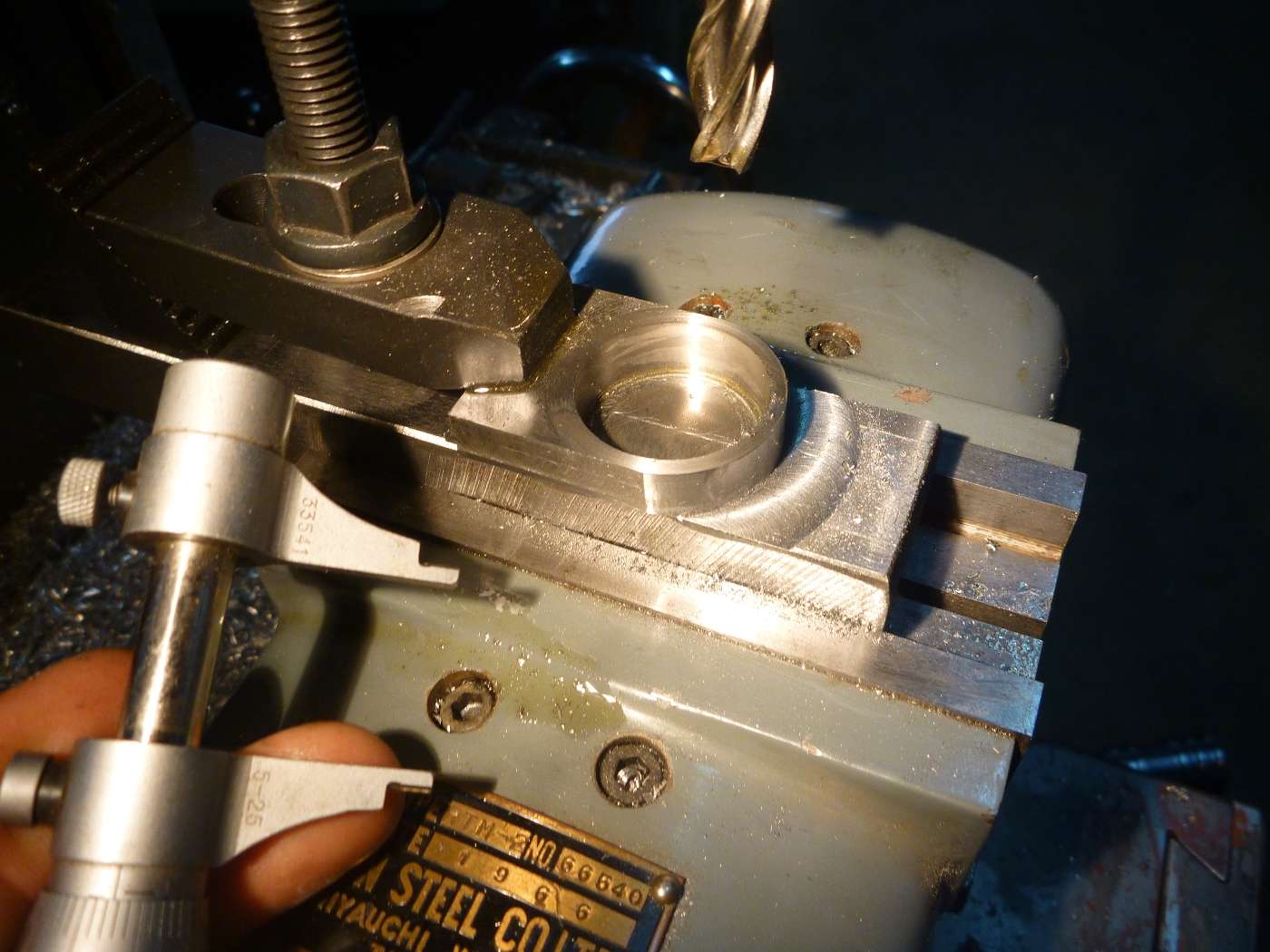

Nice work. Is that an offset boring head being used as a fly cutter (last photo in the first post)?

Similar Threads

-

SOLD: Machining book"tabletop machining"

By woodsurfer in forum METALWORK - Machinery, Equipment, MARKETReplies: 4Last Post: 7th Feb 2012, 06:52 PM

Reply With Quote

Reply With Quote